What Are You Looking For?

What Are You Looking For?

Advance International Corp. (headquartered in Hefei, Anhui Province) is deeply engaged in the biomedical packaging industry, with the core mission of "safely delivering every life specimen." We understand the unique nature of biological specimens—their safe transportation is directly linked to the accuracy of scientific research, the reliability of clinical diagnoses, and even public health. Therefore, from raw material selection to finished product delivery, every step is guided by rigorous standards exceeding industry standards.

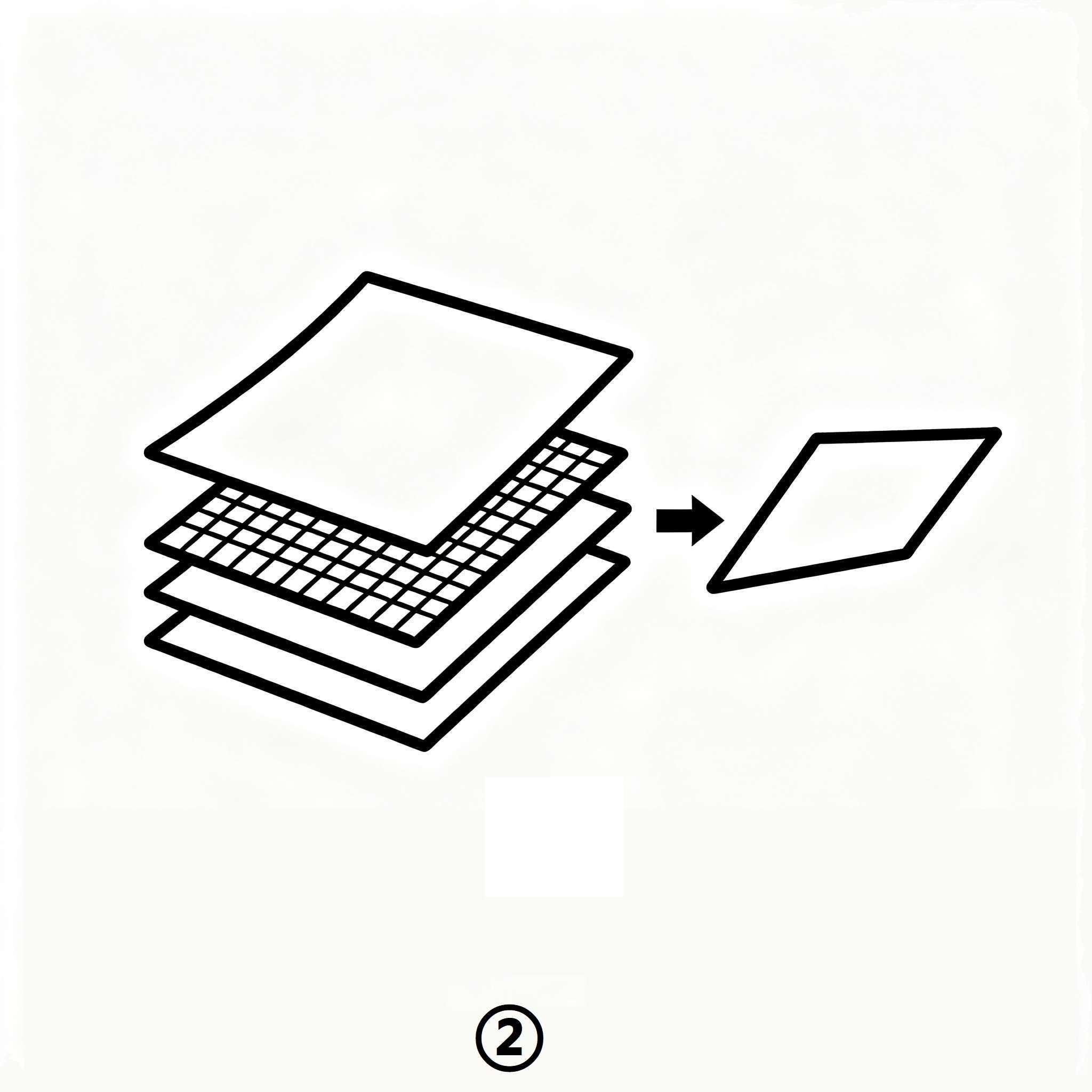

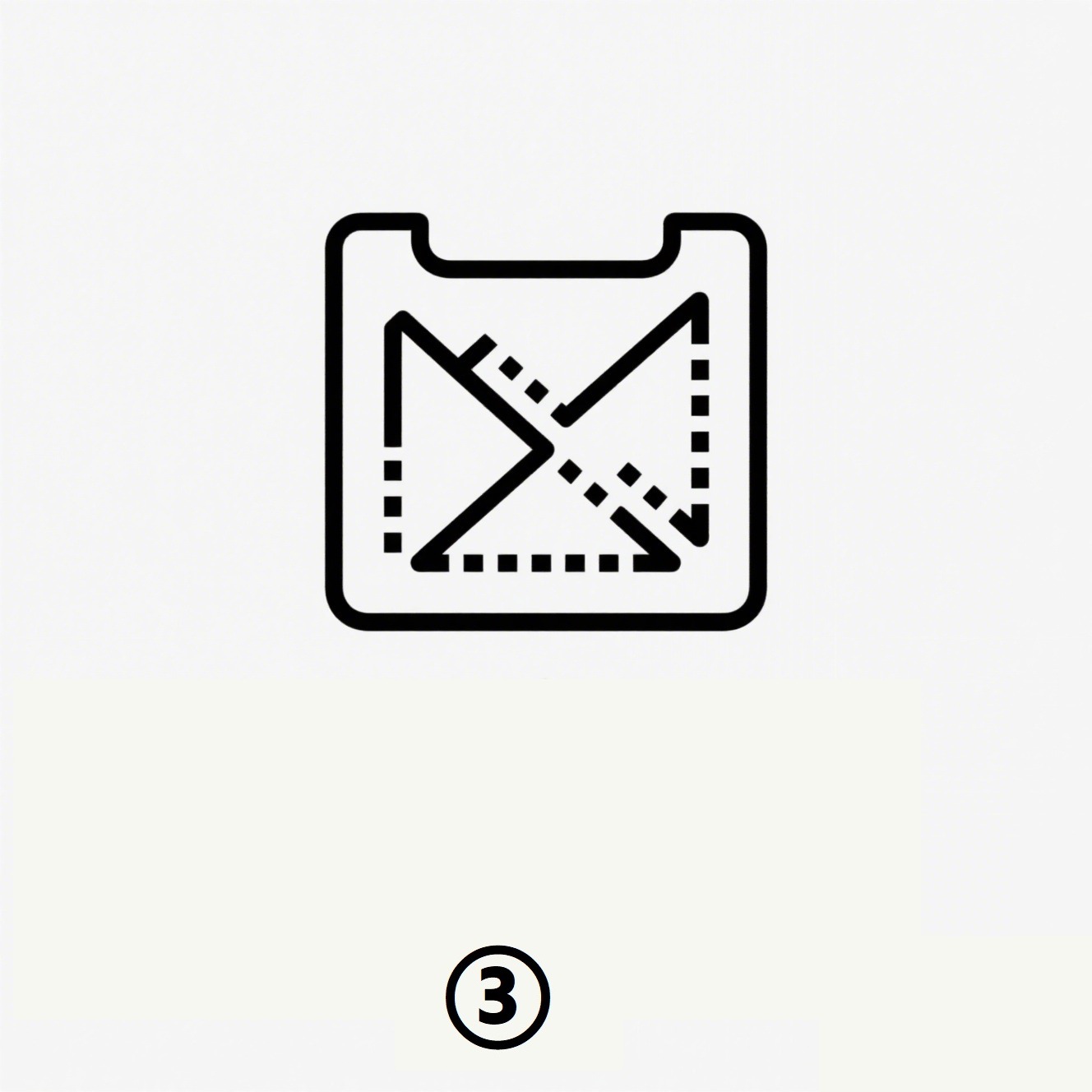

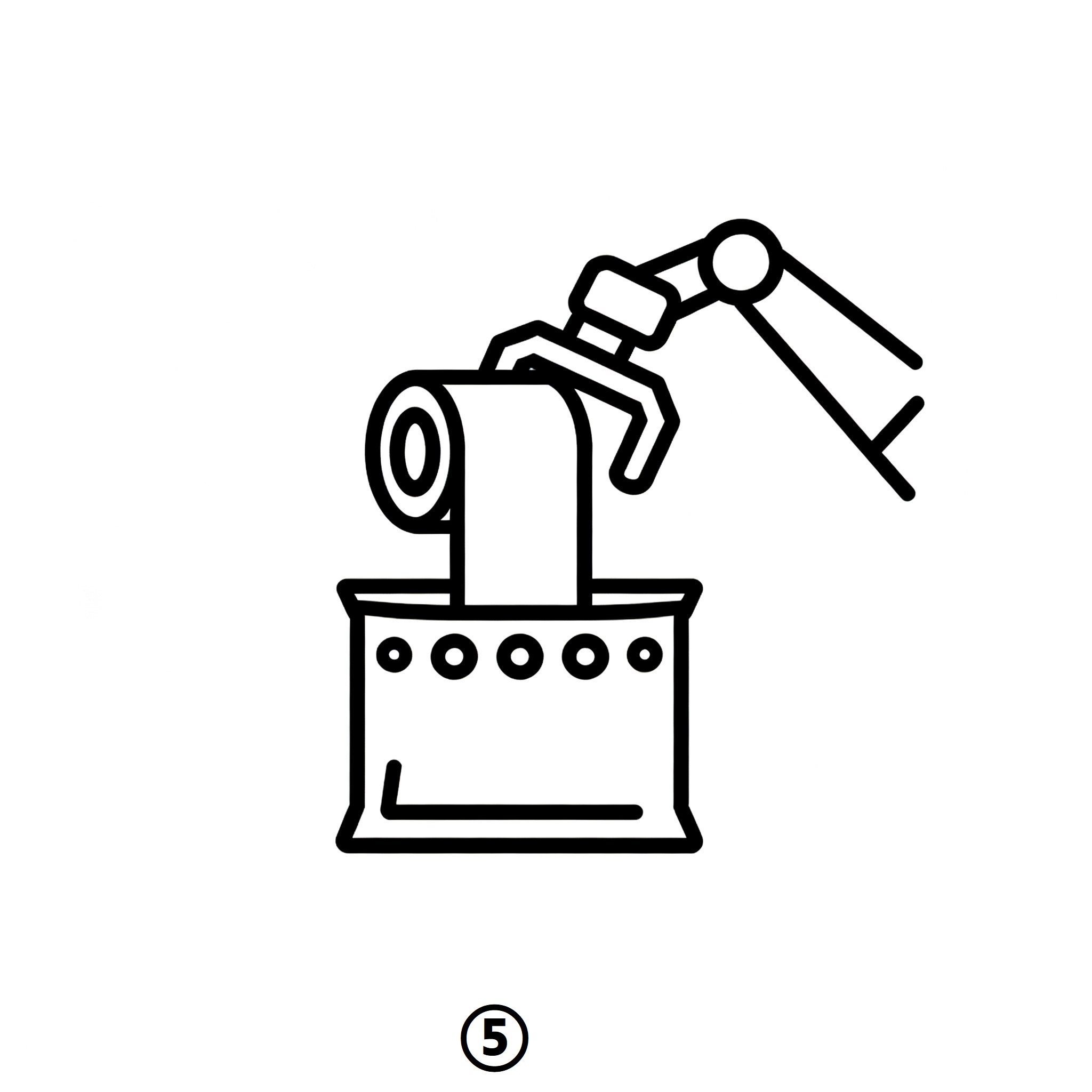

Leveraging our intelligent production lines and professional technical team at our Hefei production base, we specialize in the research and development and manufacturing of biological specimen transport bags. We not only strictly adhere to the ISO 13485 medical device quality management system and UN3373 biosafety transport regulations, but also offer customized services (such as OEM/ODM) to meet the diverse needs of our global customers. The following details our full production process for biological specimen transport bags, showcasing the meticulous craftsmanship and rigor of every step from raw material to finished product.

Customized Manufacturing to Your Specifications: If you have a clear product design, our OEM services are tailored to your specifications. We utilize state-of-the-art production equipment and highly skilled staff to bring your design to life. Whether producing a specific quantity of existing bio-bags with your branding or custom-producing bio-bags based on your unique design, we ensure precision and quality at every step of the production process.

Branding and Packaging Customization: In addition to manufacturing the products, we offer comprehensive branding and packaging customization options. We can apply your company logo, labels, and product information to the bio-bags, as well as design and produce custom packaging that meets your branding and marketing needs. This includes selecting the appropriate packaging materials, such as eco-friendly materials, and ensuring that the packaging provides adequate product protection during storage and transportation.

Full-Scale Design and Development Services: Our ODM services are ideal for clients who have a concept or idea but need assistance turning it into a fully-fledged product. Our experienced team of designers, engineers, and material specialists will work closely with you from the earliest creative stages. We conduct in-depth market research to understand the latest trends and customer needs in the biobag industry, then leverage this knowledge to create innovative and practical product designs.

From concept to market: Starting with concept sketches and 3D models, we refine the design based on your feedback and engineering feasibility. Once the design is finalized, we move into the prototyping phase. Our prototyping process utilizes advanced manufacturing techniques to create physical models of the product for testing and validation. After thorough testing and necessary adjustments, we scale up production to ensure the final product meets the highest quality standards and is ready for market. We also assist with product certification and regulatory compliance, handling all the details for you to make the concept-to-market journey as smooth as possible.

Design Submission: You submit a detailed product design, including technical drawings, material specifications, and other relevant documents.

Preliminary Review and Quote: Our team reviews your design to ensure it's manufacturable. We then provide you with a comprehensive quote, including production costs, estimated delivery time, and any additional fees for customization.

Sample Production: After your quote is approved, we produce a product sample based on your design. This sample is sent to you for review and approval.

Mass Production: Once you're satisfied with the sample, we initiate mass production. Throughout the production process, we maintain strict quality control and utilize advanced testing techniques and equipment to ensure that each product meets your specifications.

Branding and Packaging: During production, we apply your desired branding elements and prepare the product for packaging.

Delivery: After production and packaging are complete, we arrange for product delivery to your designated location. We work with reliable logistics partners to ensure timely and safe delivery.

Creative Consultation: You share your product idea, market objectives, and any specific requirements with us. Our team conducts an initial evaluation and provides insights into the feasibility and potential of your idea. Market Research and Design Concepts: We conduct in-depth market research to identify trends, competitors, and customer needs. Based on this research, our design team develops multiple design concepts for your product, presenting them to you in the form of sketches and 3D renderings.

Design Refinement and Prototyping: Once you select a design concept, we further refine it based on your feedback. We then use advanced manufacturing techniques to produce a prototype. The prototype is tested for functionality, durability, and usability.

Final Design Approval and Production Planning: After the prototype is approved, we finalize the design and develop a detailed production plan. This includes determining the bill of materials, production process, and quality control measures.

Mass Production, Branding, and Packaging: Similar to the OEM process, we initiate mass production, apply your branding, and package the product according to your specifications.

Product Certification and Delivery: Prior to delivery, we ensure that the product complies with all relevant industry standards and obtains the necessary certifications. We then arrange for the safe delivery of the product to your desired location.

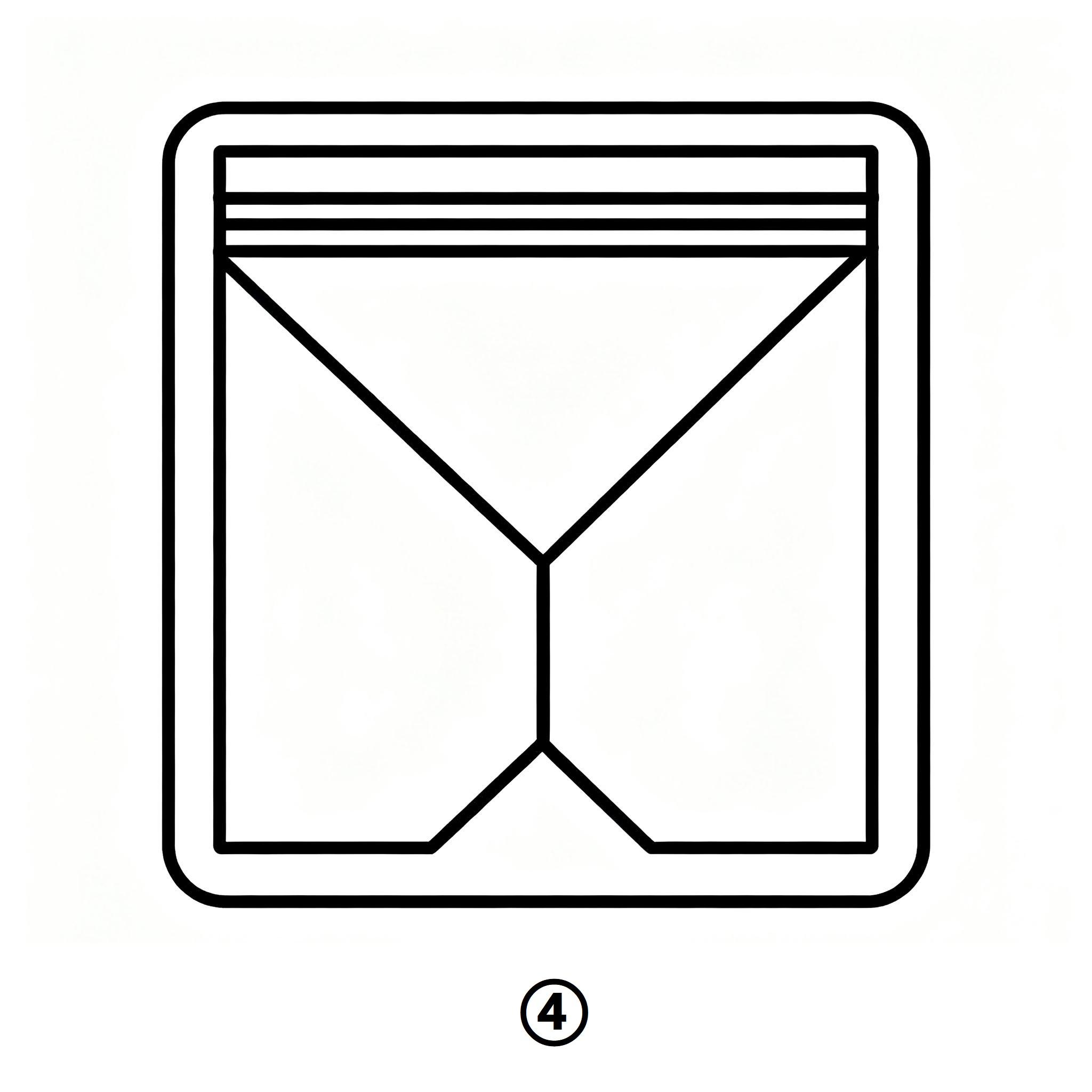

It is suitable for the daily transportation of clinical samples in hospitals at all levels and physical examination centers, including venous blood, capillary blood, urine, cerebrospinal fluid, tissue biopsy samples, etc. The product can be directly used to hold sample tubes/centrifuge tubes (compatible with conventional specifications of 2ml-50ml).

Its 95kPa pressure resistance can withstand pressure fluctuations during in-hospital elevator vibrations and cross-hospital cold chain transportation. The multi-layer composite film’s leak-proof design prevents sample spillage and contamination, while complying with the hospital’s requirements for "medical-grade non-migration" to ensure the safety of clinical sample transportation and the accuracy of test results.

It meets the transportation needs of scientific research samples in university life science laboratories and biotechnology companies, including cell suspensions, gene sequencing samples (e.g., DNA/RNA samples), microbial strains, etc. Addressing the characteristics of scientific research samples—"temperature sensitivity and contamination prevention"—the product’s low-temperature resistance adapts to cold chain transportation at -20℃/-80℃ (e.g., when used with dry ice packaging).

Its 95kPa sealing performance prevents sample leakage due to pressure changes during long-distance transportation (such as cross-city or cross-country). Additionally, it supports customized printing of "sample type labels and cold chain temperature range reminders" to facilitate the precise management of scientific research samples.

It provides compliance support for the transportation of virus/bacteria samples (e.g., influenza virus, COVID-19 samples) and suspected infectious samples in disease control and prevention centers (CDCs) and customs quarantine for emergency prevention and control. Fully adhering to the UN3373 biosafety transportation standards (requirements for Class B biological substance transportation), the product’s puncture resistance and impact resistance can cope with complex environments during emergency transportation (such as bumpy transportation after field sampling). The multi-layer barrier film effectively prevents microbial leakage, building a "safety barrier" for public health emergency response.

It caters to the "centralized testing of multi-source samples" needs of third-party medical testing institutions and independent laboratories, covering tumor marker testing samples, allergen testing samples, animal quarantine samples, etc. It supports customization of different sizes (e.g., small specifications for 10ml blood collection tubes and large specifications for 100ml tissue preservation solution). The unified 95kPa pressure standard ensures the consistency of transportation for samples of different batches and types. Meanwhile, the bag body can be printed with "testing institution LOGO and sample number QR code", enabling full traceability of samples from collection to testing and improving the efficiency of the testing process.

Our team has extensive experience in manufacturing 95kPa biological specimen transport bags and UN3373-compliant packaging. We have a comprehensive understanding of medical-grade films (such as LDPE and PET), multi-layer lamination processes, and core biosafety transport standards (UN3373 and IATA).

Leveraging extensive collaborations with both startups exploring innovative specimen packaging formats and established medical companies expanding their biosafety transport product lines, we can accurately identify customized transport bag requirements for diverse scenarios and provide OEM/ODM solutions that are both UN3373-compliant and resonate with your brand.

Quality is at the heart of Advance. From sourcing medical-grade raw materials to final inspection of our 95kPa transport bags, we adhere to closed-loop quality control throughout the entire process. Our production facilities are equipped with high-precision testing equipment (such as positive pressure seal testers and film peel strength testers), allowing our dedicated team to promptly identify potential issues such as heat-seal defects and film delamination.

We strictly adhere to international standards such as IATA and UN3373, ensuring that every OEM/ODM biological specimen transport bag (including the 95kPa model) consistently passes core tests such as "no leakage at 95kPa" and "low-temperature/puncture resistance," helping your brand establish a reliable reputation in the field of biosafety transport.

Understanding the cost sensitivity of the biomedical industry, we optimize the multi-layer composite film production process (such as streamlining energy consumption and time during the coating and curing stages) and integrate the medical raw material supply chain (through deep collaboration with leading film suppliers). This allows us to offer highly competitive pricing for OEM/ODM services for products such as 95kPa biological specimen transport bags. Whether you're customizing small batches of "UN3373-compliant laboratory transport bags" or mass-producing "95kPa commercial-grade transport bags," we can help you control costs and increase profit margins while ensuring compliance with standards and uncompromising quality.

Advance's production lines and services offer exceptional flexibility: From modifying the dimensions and printing content of existing 95kPa transport bags (such as adding brand logos and traceability QR codes) to developing specialized UN3373-compliant transport bags (such as multi-layer leak-proof structures and specifications to accommodate oversized sample containers), we can efficiently handle these needs.

Whether you're a new company entering the biological sample transport business (needing small-batch prototype verification) or an established brand expanding its 95kPa product line (needing large-scale production), we offer customized support tailored to your business stage, allowing you to grow with your business.

In today's modern business environment, success hinges not only on high-quality products but also on the ability to provide a unique service experience. Our trade company specializes in four main areas: food additives, disposable protective gloves, dental beauty products, and sample transport bags. We are committed to delivering unparalleled products and services to our customers. Here is how we create value through uniqueness:

In the realm of food additives, we understand the paramount importance of safety and quality. Our products not only comply with international food safety standards such as ISO and HACCP certifications but also incorporate continuous technological innovations to offer more efficient and eco-friendly solutions. For instance, our antioxidants use natural ingredients that not only extend the shelf life of food products but also enhance their nutritional value. Additionally, we provide customized services, developing specific formulations based on individual customer needs, ensuring your products stand out in the market.

Our disposable protective gloves are widely used in medical, laboratory, industrial, and household settings. We offer various materials including latex, nitrile, and PVC to meet different scenario requirements. Notably, while ensuring high elasticity and durability, our gloves also prioritize comfort during wear. Through advanced manufacturing processes, our gloves present minimal risk of allergic reactions, providing users with the safest protection experience possible.

In the field of dental beauty, our product range includes teeth whitening agents, orthodontics, and restorative materials. We focus not only on functionality but also on aesthetic results. For example, our teeth whitening agents utilize the latest hydrogen peroxide technology to significantly brighten teeth in a short time while minimizing damage. We also offer professional training and support to help dental practitioners maximize the effectiveness of our products, delivering optimal treatment results for patients.

Our sample transport bags feature a reasonable design and excellent sealing to ensure samples remain uncontaminated during transport. Made from high-quality materials, these bags are durable and tear-resistant, suitable for harsh environmental conditions. Additionally, we provide customization services, tailoring different specifications and labeling according to customer needs, ensuring a smoother and safer sample transportation process.

General Service Features:

a) Logistics and Delivery: Our efficient logistics system ensures fast and timely delivery. No matter where you are located, we can promptly deliver products to you.

b) Customer Service: We offer 24/7 online customer service to address any inquiries. Our customer service team is professionally trained to provide the most attentive service.

c) After-Sales Support: We have a comprehensive after-sales service system to handle returns and exchanges. We commit to resolving your issues in the shortest time, ensuring your satisfaction.

d) Continuous Improvement: We continuously gather customer feedback to optimize our products and services. We believe that only through constant progress can we provide the best experience for our customers.

Our company is dedicated to providing unique products and services through innovation and quality. Whether it’s food additives, disposable protective gloves, dental beauty products, or sample transport bags, we hold ourselves to the highest standards, ensuring every customer receives satisfactory solutions. Choosing us means choosing excellence and trust.